Benchmark Increases Production With New HQ, Debuts Satellite Autopilot Feature

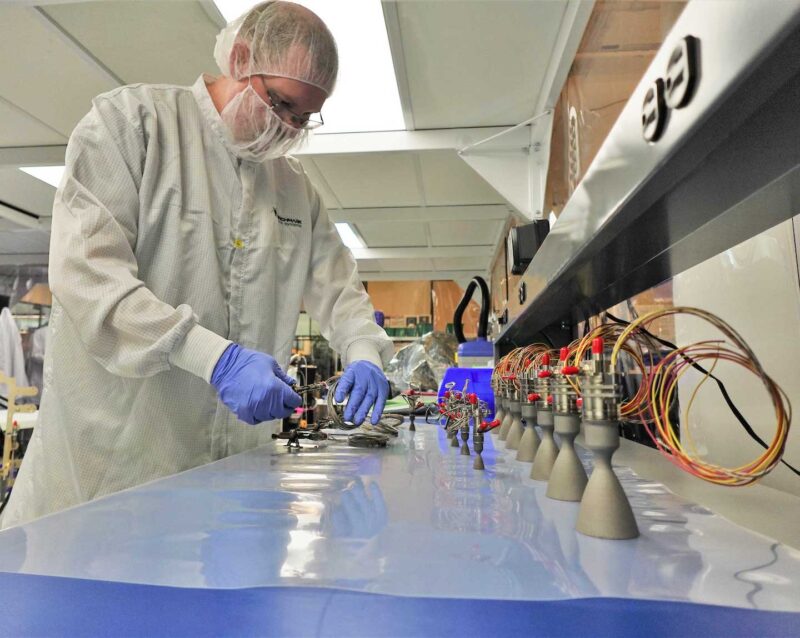

Benchmark Space Systems is opening a new 40,000 square foot production facility in Burlington, Vermont. Photo: Benchmark

Benchmark Space Systems is expanding its headquarters to ramp up production on propulsion systems, the company announced Tuesday, along with a new autopilot on-board processing feature for customer satellites.

The propulsion company recently closed a $33 million Series B round, and is investing in a new, 40,000-square foot facility to increase its manufacturing capacity by four times. The company is staying in Burlington, Vermont, and the headquarters and manufacturing facility is near its previous headquarters.

Ryan McDevitt, Benchmark’s CEO, tells Via Satellite the new facility will allow the company to deliver on its backlog. The company has more than 1,000 thrusters to be built and tested, representing 250-plus systems. Public customers include The Exploration Company and Space Forge.

“The big push for making this move right now is watching our customers who are setting up their factories, their manufacturing capabilities, and making sure that we were time-phased appropriately,” McDevitt said. “18 months ago, people were building their demo units and we were in the same boat. Now they’re going to build a dozen or more a month, and Benchmark has to be ready to do the same, across multiple customers.”

McDevitt said the industry conversation around in-space mobility, collision avoidance, and responsible use of space is driving a lot of business for the propulsion company.

The new facility moves testing in-house, to improve the flow of production, COO Wesley Grove tells Via Satellite. “A big part of what we’re doing moving into the new facility is laying out end-to-end flow lines for our production. From receiving and inventory management, through to production and test, having all that capability in-house,” Grove says.

Benchmark recently laid off approximately 15% of its team, CNBC reported. McDevitt told Via Satellite the restructuring was part of the company’s shift from an R&D focus to production focus. Last year, the company spent roughly 50% of its resources on R&D, which is now transitioning to production. “There were some places that we said, we’re spending heavier here than we will need to going forward, we need to reallocate those resources,” he said.

Separately, Benchmark on Monday announced SmartAIM, an onboard software control solution within Benchmark’s chemical, electric, and hybrid propulsion systems. It can function as an “autopilot” for satellites, executing autonomous space maneuvers. The company is partnering with software company Kayhan Space to integrate its Pathfinder spaceflight safety into SmartAIM to optimize maneuver planning.

CCO Chris Carella describes the product as a software layer between the satellite’s GNC stack and the propulsion system to abstract propulsion commands from the customer, and improve propulsion efficiency and reduce the need for manual work by the customer.

Carella said oftentimes when thrusters fail on orbit, investigations reveal that valves are opened and closed out of sequence, not heated right, etc. SmartAIM is meant to remedy that problem.

“By abstracting the command and being able to control what we do best within the propulsion subsystem and all the components. Customers GNC computers can now provide abstract commands at different levels and have this SmartAIM onboard software, essentially control and command the maneuver. Eventually it gets to full autonomy, but starts out in an assist mode.”