Latest News

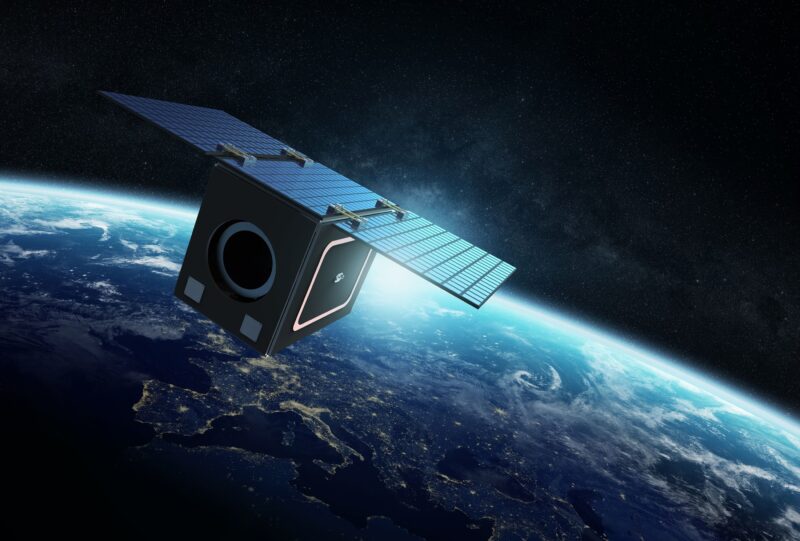

Rendering of a Millennium Space Systems-built satellite flying Spectrolab solar cells. Photo: Boeing

Boeing is applying additive manufacturing technology to solar array production for satellites, in an update the company says can improve production time by 50% compared to current timelines.

Boeing explained in a Sept. 10 announcement that it has developed a way to 3D print the solar panel structure and built-in features such as harness paths and attachment points directly into each panel. The company said this replaces dozens of separate parts and delicate bonding steps, and results in a piece that is faster to build and easier to integrate.

Flight‑representative hardware has completed engineering testing and is progressing through qualification ahead of customer missions. Boeing plans to fly the first 3D-printed solar arrays to fly Spectrolab solar cells aboard small satellites built by Millennium Space Systems — both Boeing subsidiaries.

The new array approach will be available to the market in 2026, and can be used for the 702-class spacecraft platform.

“We reached across our enterprise to introduce efficiencies and novel technologies to set a more rapid pace,” said Michelle Parker, vice president of Boeing Space Mission Systems. “By integrating Boeing’s additive manufacturing expertise with Spectrolab’s high‑efficiency solar tech and Millennium’s high‑rate production line, our Space Mission Systems team is turning production speed into a capability, helping customers field resilient constellations faster.”

Stay connected and get ahead with the leading source of industry intel!

Subscribe Now