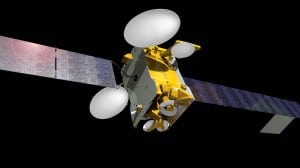

SES’ New Satellite Order Shows Increased Confidence in Hybrid Systems

[Via Satellite 02-20-2014] SES has contracted Airbus Defence and Space to manufacture its newest hybrid propulsion satellite, the SES 10. The spacecraft is the tenth satellite built on the Eurostar platform to use electric propulsion. SES 10 will have an electrical power of 13kW and its expected launch mass is approximately 5,300 kilograms. This investment in electric propulsion signals a growing industry trend toward the acceptance of its routine use, according to François Auque, head of space systems at Airbus Defence and Space.

“This new contract is a significant win for Airbus Defence and Space and … this order also demonstrates our customers’ faith in our electrical propulsion technology for station-keeping, a technology that we are among the few in the world to be able to demonstrate in orbit, something we have now been doing for 10 years,” Auque said.

SES 10 is being constructed with an electric plasma propulsion system for on-orbit maneuvers and a chemical system for initial orbit raising and maneuvering. It will replace AMC 3, which has 24 Ku-band transponders, and AMC 4, which has 12 Ku-band transponders. The new satellite will provide additional capacity at 67 degrees west for direct-to-home (DTH) television broadcasting and other telecommunication services for Mexico, the Caribbean, Central America and South America, using a payload of 50 high-power Ku-band transponders, more than both previous satellites combined.

As satellite operators become less averse to electric propulsion, they are beginning to reap the benefits of its use. Once in orbit, it serves as an efficient method of station keeping and routine orbital maintenance procedures. It also reduces the satellite’s mass by not having to carry as much fuel. This extra space allows for a lighter payload, or the option to place more transponders and equipment onboard. What started as an innovative idea is now turning into a trend for satellite manufacturing.

“We’ve seen increasing use of electric propulsion [which has] built up experience using those systems,” said Jeffrey Foust, senior analyst at Futron. “There were some problems early on with some electric propulsion systems that suffered some degradation that reduced their performance. That was the case with some of the early Boeing 702 series spacecraft that use electric propulsion. But a lot of those problems have been overcome and confidence has grown to the point that even relatively risk-averse satellite operators incorporate electric propulsion and the benefits it offers even on a hybrid basis.”

As a hybrid system, satellite operators can play off the strengths of each technology. Electric propulsion systems, though lighter, do not currently generate the same level of thrust as chemical systems. This means for all electric systems the time spent in transfer orbits is greater, making it a lengthier process to for that satellite to enter service. This also exposes the satellite to Van Allen radiation belts for a longer period of time.

SES, however, is all in. Electric propulsion is the “big push” that the company is pursuing at the moment; “the big game changer,” according to Martin Halliwell, CTO of SES. The main reason for this enthusiasm for electric propulsion is lowering the mass of the spacecraft and the cost-effective possibilities it implies.

“If we can get the mass down of the satellite, you’ve got two choices: you can either go with a small launch vehicle or you can say ‘ok, I can still stay with a six-ton envelope where I can fit a lot more gear.’ So that’s really what we’re working on very much at the moment,” Halliwell told Via Satellite back in November. “You’ll be able to launch far more complicated satellites with a much more smaller mass.”

But, in general, balancing the pros of each technology seems to be a new favorite for satellite design going forward. This also provides the familiarity of chemical propellant as a source of comfort while electric propulsion earns its stripes.

“For that reason primarily you’ve seen satellite operators opt for the hybrid approach, using chemical propulsion primarily for the orbit raising and using the electric propulsion system for the station keeping once they are in GEO, with the chemical as the backup,” said Foust. “It gets back to the base of experience. There is still a lot more experience with chemical propulsion systems than electric propulsion systems. I think as the technology continues to mature and demonstrate its capabilities, you’ll see more satellite operators at least consider if not adopt greater use of electric propulsion at least on a hybrid basis in the future.”